ROEST and Condesa Co.Lab: A tale of two coffee labs

Harry McAuley, Trade and Quality Assurance, getting ready for a cupping session.

In mid-2019, specialty coffee importer Condesa Co.Lab celebrated its seventh birthday. Managing Director Stephen Bannister says that after those seven years of growth, the team felt established and successful.

He said that even then, the team was optimistic about the future – however, he also acknowledges that they weren’t entirely prepared for what it would bring.

Stephen says that as a result, the team has come to realise they need time and space to grow. He tells me that a healthy, happy team can deliver better quality and better service for our partners, and that requires a certain amount of expansion.

In this post, he explains more about what that expansion entails, and the journey that led Condesa to partner with us here at ROEST. Read on to learn more.

“We knew that we needed to work smarter, not harder, for the benefit of ourselves and our partners”

Feeling stretched

Our lab served us well for more than seven years, and in mid-2019, we brought in a new machine to accompany our trusty common gas roaster. However, as our business continued to grow, sample roasting became more demanding and time consuming.

We certainly benefited from a little bit of respite when the second machine arrived, but even with four barrels, there were still days when the team felt chained to the roaster.

Since 2013, on average, we have roasted around 3,000 samples per year. In total, that’s about 26,000 minutes or 433 hours, which is nearly 11 working weeks. That’s a fifth of the working year spent on roasting alone.

As you can imagine, we take quality control very seriously here at Co.Lab. We cup everything multiple times before any coffee is delivered to a partner. Quality is our job, and we do not shy away from it. But we felt that something needed to change.

Condesa Co.Lab ensures quality by cupping everything multiple times before any coffee is delivered to a partner.

Recognising the need for change

To start, we wanted to look for new premises for our Co.Lab, with the intention of securing a new site by the end of 2019. When 2020 arrived, however, everything changed.

For most of us, it was a year to forget. It was a complicated and unwelcome time, but despite the difficulties, there was also opportunity. The unprecedented challenges of the year forced Co.Lab to change for the better.

All across the coffee industry, we apply the same SCA and CQI processes to grade and review coffee. The problem with the pandemic was that we were unable to travel, unable to cup, and unable to communicate in perfect. As hard as you might try, you simply can’t do quality control over the internet.

As the first wave of the pandemic passed, we took a moment to breathe and reflect. This gave us some much needed perspective. It was then that we knew we needed to take our new lab in a different direction.

We resolved to empower the people in our team by supporting them to embrace technology. We knew that we needed to work smarter, not harder, for the benefit of ourselves and our partners.

As we arrived at the end of 2020, we knew we had no other option but to adapt. The world was not the same, and it would take time to move forward.

One of the three ROESTS owned by Co.Lab, making sure the team is given enough time to prepare samples that will meet their partners expectations.

ROEST x Condesa Co.Lab

Driving this kind of positive change can be easier said than done. But as we moved forward, we made sure our focus was on one thing above all else: creating more time for our team.

Time is, after all, the most important thing that we can give our coffee lab teams to support them. It ensures all the skills we have learned cupping can be put into the next round of samples to make sure they meet our expectations.

Ultimately, time ensures that the samples we send to our partners meet their expectations. At the same time, time also lets us discuss and align the analysis of a coffee with those partners, allowing us to build trust.

Creating time is one of Co.Lab's key purposes, both for our partners and our own team. To that end, we have welcomed three ROEST sample roasters into our lab, all the way from Norway. In true Scandinavian spirit, they are stylish, tidy, always on time, and always ready to give their all for Co.Lab.

Moving to an automated roasting system has enabled us to:

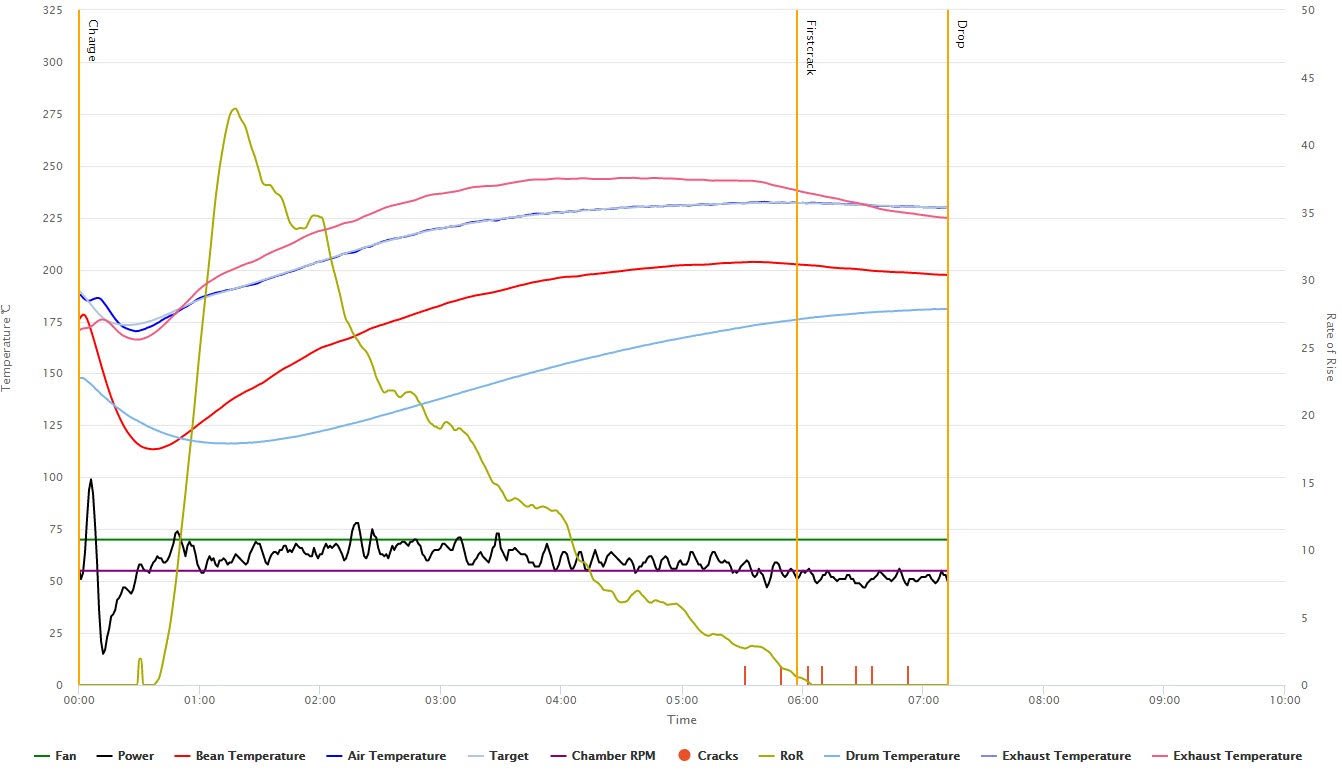

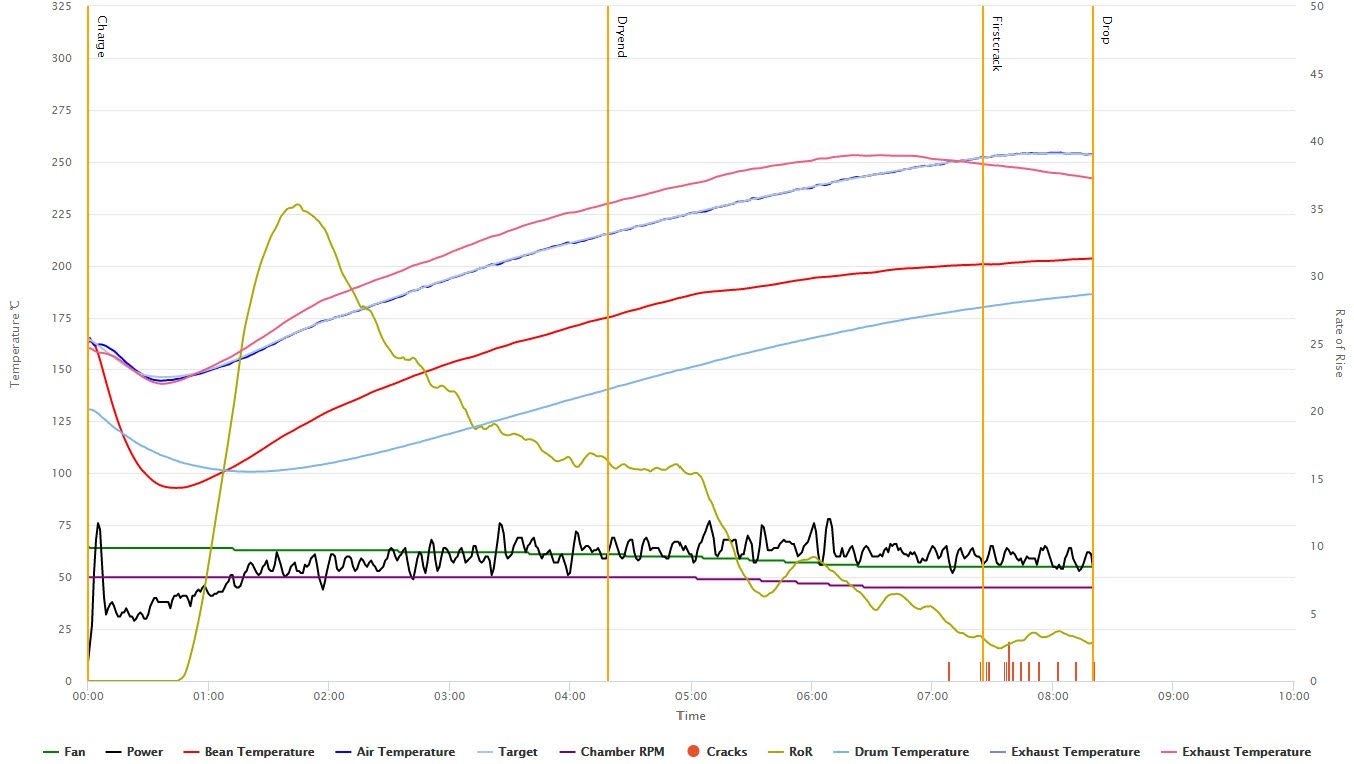

Build a library of producer-consistent profiles

Give better information about roasted samples to partners

Tailor a roast irrespective of variety, process, origin, or density, allowing for clean and transparent roasts with enough development to allow people to assess the coffee and its key characteristics

Share profiles and improve our own learning with transparent dialogue about how coffee is roasted

Monitor roasting from remote locations to improve the quality of the process

Enhance safety protocols with automated batch dropping

Embrace new features to work on incremental improvements for the benefit of all users in the future

Profiles by Condesa Co.Lab - download and give them a go!

Throughout the whole purchase process Condesa receives several samples to continually check the health of each coffee.

Our primary incentive for using this automated roasting system is to improve quality outcomes for our partners. However, as a secondary benefit, our Co.Lab is now a healthier place to work, as our team spends less time roasting.

In turn, this means we can spend more time sourcing and delivering high-quality coffee for our partners.

To share this with the coffee community, the Condesa Co.Lab Coffee Lab in Sydney will be open for roasters to come and work with these incredible ROEST machines. Please get in touch with Eli at qualitylab@condesa.com.au if you’re interested, or just reach out for a chat.

Written by the Condesa Co.Lab team

Photo courtesy of Condesa Co.Lab